Product Category

MAIN PRODUCTS

Contact Us

Grace Lee

Grace Lee

weathering steel plate new offer

Product Details

What is weathering steel plate?

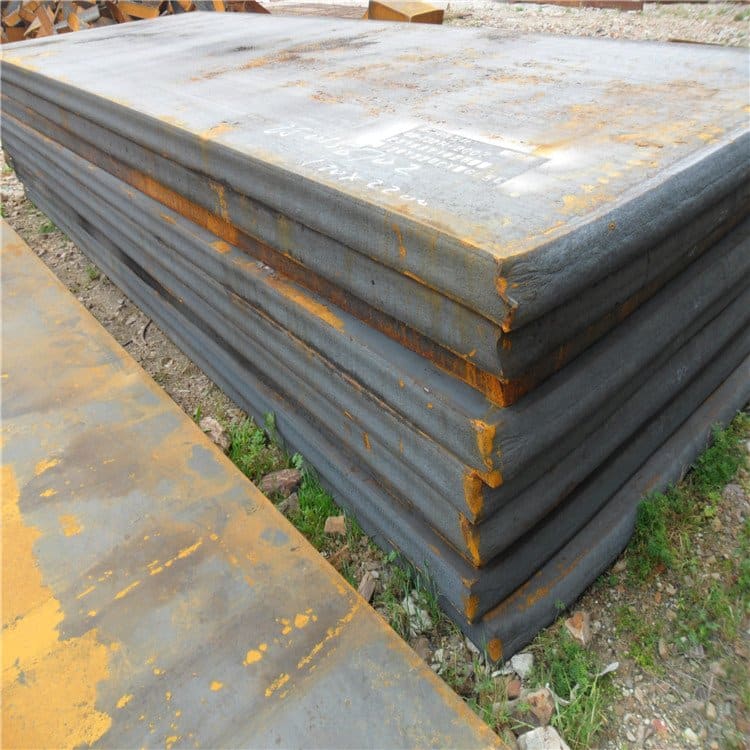

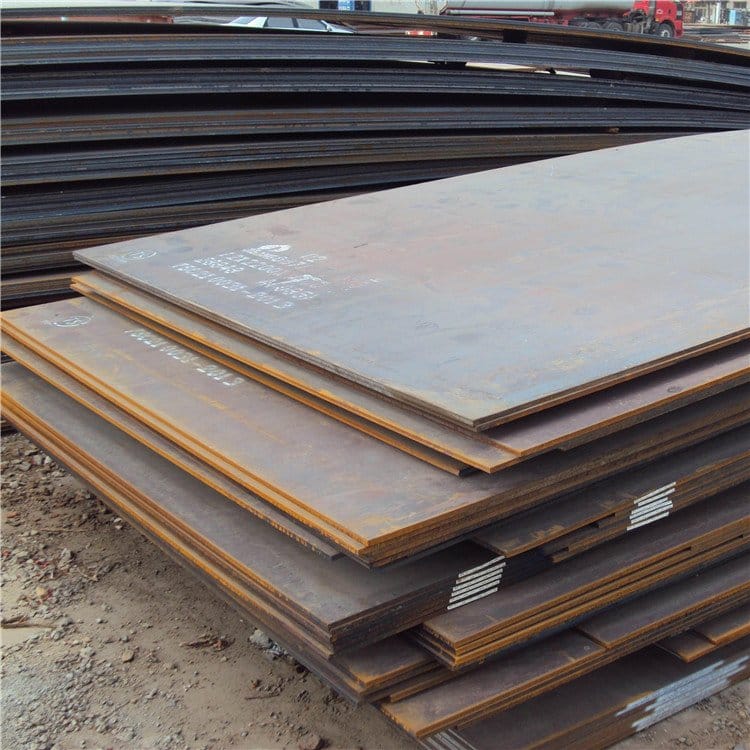

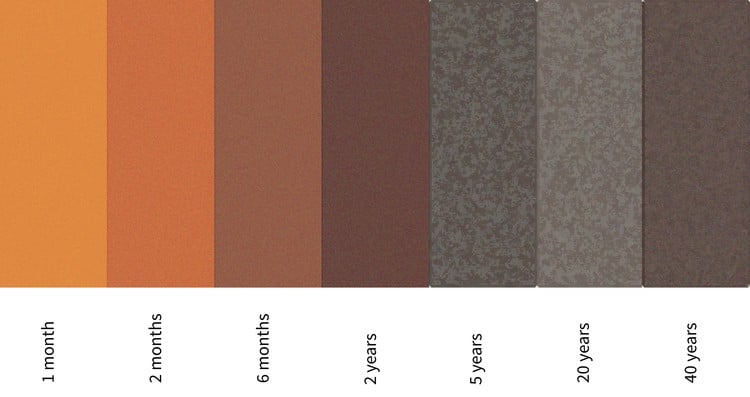

Weathering steel plate, also known as corten steel or COR-TEN steel, is a type of alloy steel that naturally develops a rust-like coating when exposed to various atmospheric conditions. This rust-like coating protects the steel from further corrosion and serves as a protective barrier. Weathering steel is commonly used for outdoor structures such as bridges and buildings.

Corten steel, also known as weathering steel, is a special steel originally developed for bridge building and skyscraper construction due to its incredible strength. It develops a protective rust-like coating when exposed to the elements, protecting the steel beneath. It has since been used for a variety of applications, from fencing to garden furniture.

What’s the application of weathering steel plates?

Weathering steel plates are used in a wide variety of applications, including bridges, railcars, buildings, transmission towers, sculptures, and industrial and agricultural equipment. The unique properties of weathering steel make it an ideal material for many outdoor applications, especially in areas with high humidity, salt spray, and other corrosive elements. Weathering steel is also used for facades, roofing, and siding in both residential and commercial buildings.

What’s the Advantages of weathering steel plates?

1. Weathering steel is highly corrosion resistant, making it an ideal choice for outdoor structures.

2. It is extremely durable, withstanding years of exposure to the elements without requiring additional protection.

3. Weathering steel has a unique aesthetic, creating a beautiful patina that can add character and charm to any outdoor space.

4. It is low maintenance, requiring little to no upkeep.

5. Weathering steel is an environmentally friendly option, as it is made from recycled materials and can be recycled again at the end of its life.

Corten steel avoids the volatile organic compounds from painting and the disposal of blast-cleaning debris from maintenance work in the future.

Corten Steel Panel Specifications:

| Application | Construction |

|---|---|

| Thickness | 8-150mm |

| Material | Corten Steel |

| Grade | Corten Steel Plate, A558, S355JOW, S355JOWP, S355J2W, Q235NH, Q295NH, Q355NH, Q460NH,Q550NH, Q295GNH, Q355GNH |

| Shape | Plate |

| Surface Treatment | MILLS FINISIH, PRE-RUSTED TREATMENT |

| Application | Facade, planter, screen , fence, edging, fire pit, tree grate |

|---|---|

| Thickness | 0.5-20 mm |

| Material | Corten Steel |

| Grade | CORTEN A & B, A242, SPA-H, A606, S355JOW, S355JOWP, S355J2W |

| Shape | Coil & sheet |

| Surface Treatment | MILLS FINISIH, PRE-RUSTED TREATMENT |

weathering steel plate thickness is huge you can choose the one which is appropriate for your industry that looks better in-app factors. Talking about the length then it also comes in many starting from 2m to 12m etc. as a buyer you have lots of choices.

Comparison of Different Weathering Steel Grades

| Material | Chemical Composition,% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cu | Cr | Ni | V | |

| Q235NH | ≤ 0.13 | 0.10-0.40 | 0.20-0.60 | ≤ 0.13 | ≤ 0.13 | 0.25-0.55 | 0.40-0.80 | ≤ 0.65 | / |

| Q295NH | ≤0.15 | 0.10-0.50 | 0.60-1.00 | ≤ 0.13 | ≤ 0.13 | 0.25-0.55 | 0.40-0.80 | ≤ 0.65 | / |

| Q295GNH | ≤ 0.12 | 0.10-0.40 | 0.20-0.50 | ≤ 0.13 | ≤ 0.13 | 0.25-0.55 | 0.40-0.80 | 0.25-0.50 | / |

| Q355NH | ≤ 0.16 | ≤ 0.50 | 0.50-1.50 | ≤ 0.13 | ≤ 0.13 | 0.25-0.55 | 0.40-0.80 | ≤ 0.65 | / |

| Q355GNH | ≤ 0.12 | 0.20-0.75 | ≤ 1.00 | ≤ 0.13 | ≤ 0.13 | 0.25-0.55 | 0.40-0.80 | ≤ 0.65 | / |

| 09CuPCrNi-A | ≤ 0.12 | 0.20-0.75 | 0.20-0.50 | 0.060-0.12 | ≤ 0.020 | 0.25-0.50 | 0.30-1.25 | 0.12-0.65 | / |

| 09CuPCrNi-B | ≤ 0.12 | 0.10-0.40 | 0.20-0.50 | 0.060-0.12 | ≤ 0.020 | 0.25-0.50 | 0.30-0.65 | 0.25-0.50 | / |

| 05CuPCrNi | ≤ 0.090 | 0.25-0.50 | 0.20-0.50 | 0.060-0.12 | ≤ 0.020 | 0.25-0.50 | 0.30-1.25 | 0.12-0.65 | / |

| B480GNQR | ≤ 0.12 | 0.25-0.75 | 0.20-0.50 | 0.070-0.15 | ≤ 0.030 | 0.25-0.55 | 0.30-1.25 | ≤ 0.65 | / |

| Q450NQR1 | ≤ 0.12 | ≤ 0.75 | ≤ 1.50 | ≤ 0.025 | ≤ 0.020 | 0.20-0.55 | 0.30-1.25 | ≤ 0.65 | / |

| SPA-H | 0.05-0.12 | 0.25-0.75 | 0.20-0.60 | 0.070-0.12 | ≤ 0.025 | 0.25-0.50 | 0.30-1.25 | ≤ 0.65 | / |

| Cor-ten A | 0.15 | 0.25-0.75 | 0.20-0.50 | 0.07-0.15 | 0.03 | 0.25-0.55 | 0.50-1.25 | 0.65 | / |

| Cor-ten B | 0.19 | 0.30-0.50 | 0.80-1.25 | 0.035 | 0.03 | 0.25-0.40 | 0.40-0.65 | 0.4 | 0.02-0.10 |

| S355JOW | 0.16 | 0.5 | 0.50-1.50 | 0.035 | 0.035 | 0.25-0.55 | 0.4-0.8 | / | / |

| S355JOWP | 0.12 | 0.75 | 1.00 | 0.06-0.15 | 0.035 | 0.25-0.55 | 0.30-1.25 | / | / |

| S355J2W | 0.16 | 0.5 | 0.50-1.50 | 0.03 | 0.03 | 0.25-0.55 | 0.40-0.80 | / | / |

| Material | Mechanical properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Yield Strength N/mm² min | Tensile Stremgth N/mm² | Elongation % min | |||||||

| ≤ 16 | 16-40 | 40-60 | >60 | ≤ 16 | 16-40 | 40-60 | >60 | ||

| Q235NH | 235 | 225 | 215 | 215 | 360-510 | 25 | 25 | 24 | 23 |

| Q295NH | 295 | 285 | 275 | 255 | 430-560 | 24 | 24 | 22 | |

| Q295GNH | 295 | 345 | / | / | 430-560 | 24 | 24 | /23 | / |

| Q355NH | 355 | 345 | 335 | 325 | 490-630 | 22 | 22 | 21 | 20 |

| Q355GNH | 355 | 345 | / | / | 490-630 | 22 | 22 | / | / |

| 09CuPCrNi-A | ≥345 | ≥480 | ≥24 | ||||||

| 09CuPCrNi-B | ≥295 | ≥431 | ≥24 | ||||||

| 05CuPCrNi | ≥310 | ≥440 | ≥26 | ||||||

| B480GNQR | ≥350 | ≥480 | ≥22 | ||||||

| Q450NQR1 | ≥450 | ≥550 | ≤ 6: ≥22 | >6-14: ≥20 | ≥14: ≥19 | ||||

| SPA-H | ≥355 | 490-610 | ≤ 6: ≥22 | >6-12: ≥ 15 | |||||

| Cor-ten A | ≥345 | ≥485 | ≥20 | ||||||

| Cor-ten B | ≥345 | ≥485 | ≥19 | ||||||

| S355JOW | <16: ≥355 | >16-80: ≥ 345 | >80-100: ≥ 315 | >100-150: ≥ 295 | >3: 510-680 >3-100: 470-630 >100-150: 450-600 | ||||

| S355JOWP | <16: ≥355 | >16-150: ≥ 345 | >3: 510-680 >3-100: 470-630 | ||||||

| S355J2W | <16: ≥355 | >16-80: ≥ 345 | >80-100: ≥ 315 | >100-150: ≥ 295 | >3: 510-680 >3-100: 470-630 >100-150: 450-600 | ||||